|

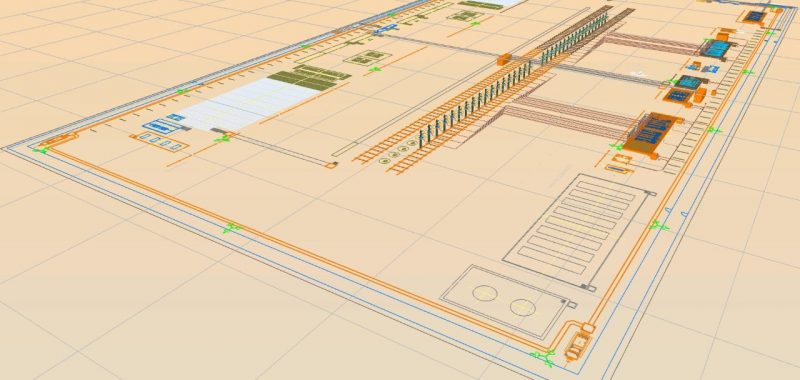

One of the flagship projects of the oil sector for the end of 2019 in block 43 (ITT) – Ecuador, with which Petroamazonas EP begins production of around 10,000 barrels per day and a future production peak of 125,000 barrels per day. .

This is a comprehensive engineering project developed based on experience in the design of surface facilities, civil works and works in sensitive environments, providing the client with security, savings, projection and optimization of their processes.

Improvement of the Production Water Collection System at Dorine Battery Station – Andes Petroleum |

Replacement of an existing crude oil tank with a new process water tank, adaptation of existing facilities, implementation of new instrumentation and automation of the process, improving the quality and increasing the capacity of the injection water system in Block 17 – Andes Petroleum ,

An engineering developed with high standards, design proportional to the need, oriented so that the manufacturing work is carried out mostly in the workshop, reducing the time of work in the field through procedures and installation strategies, and most importantly, without affect the normal operation of different systems.

Optimization of Production Equipment: Internal Gunbarrel, CPF Production. |

Increased the Installed Capacity of the Plant, to Achieve the Requirement of Quality of Sale of the Oil Produced, Optimizing Existing Equipment.

Through our Computational Fluid Dynamics (CFD)-based solution, optimization studies of Gun barrels Interns were Performed, Allowing to Significantly Improve the Performance of the Equipment, at a Cost Equivalent to the Fraction of a New Equipment.

|

Development of Engineering, Construction, and Commissioning of Expansion to a Ventilation System of the Production Area through (CFD) tools.

The solution was Developed Using State-of-the-art Computational Numerical Simulation Tools (CFD) , which Guarantee the Suitability and Performance Required for the Ventilation System.